See risk before it becomes downtime.

We turn raw SCADA and inverter data into clear, prioritized actions — so your team focuses only on what truly matters.

Too much data. Not enough clarity.

SCADA systems generate thousands of signals every day

Engineers are forced to manually inspect dashboards and alarms

Early warning signs are often missed

Maintenance decisions are reactive instead of proactive

Most teams don't lack data. They lack prioritization.

Operational risk, clearly prioritized.

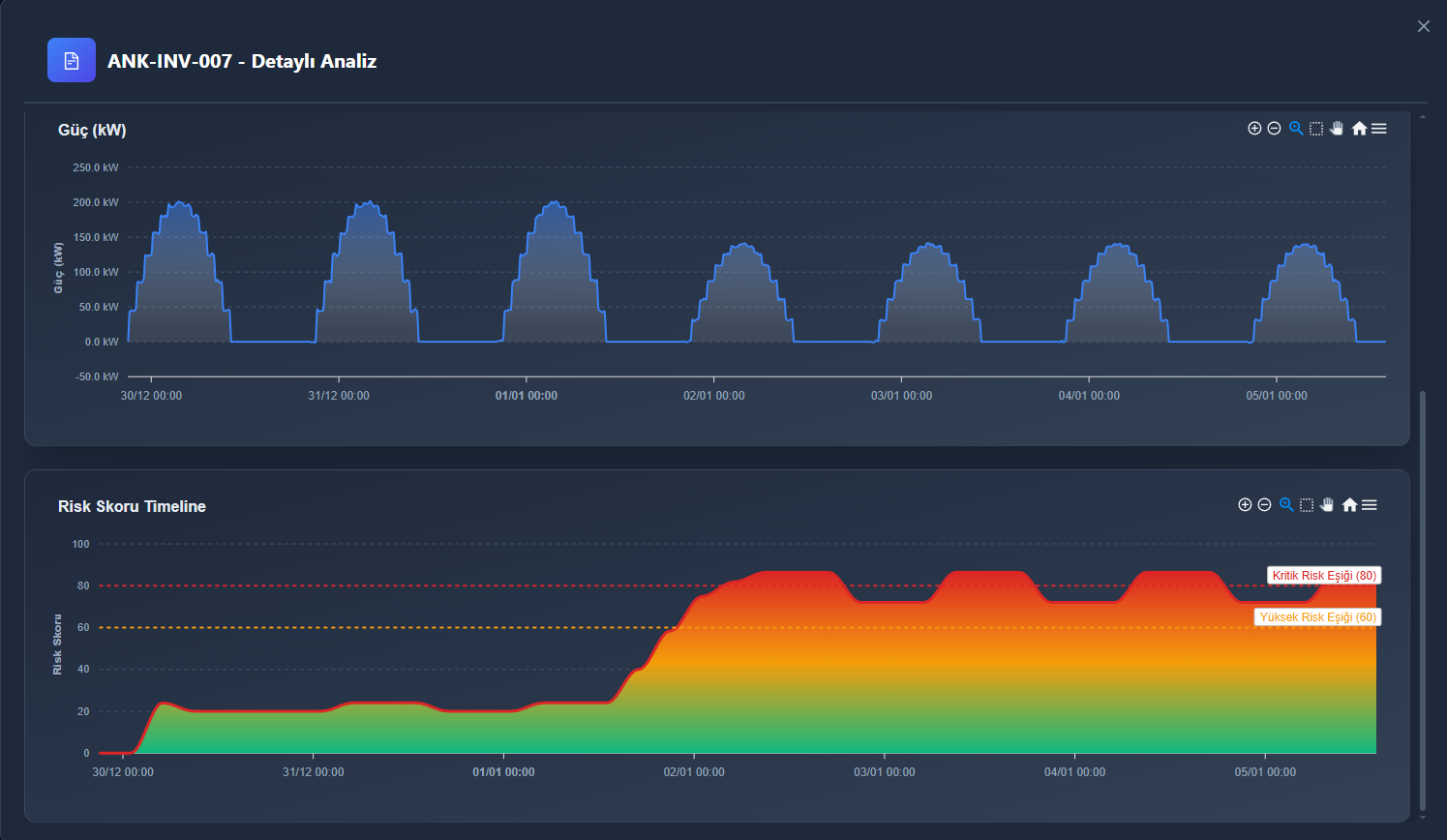

Our platform continuously evaluates asset behavior and assigns a clear risk score to each piece of equipment. Instead of reviewing endless charts, teams instantly see where attention is required.

Asset-level risk scoring

Anomaly and trend detection

Peer comparison across similar equipment

Clear explanations behind each risk signal

Why It's Different

Not another monitoring dashboard

Focused on prioritization, not raw data

Designed to support engineering judgment, not replace it

Transparent risk logic — no black-box decisions

How It Works

Ingest operational data from existing systems

Analyze behavior over time and across similar assets

Normalize signals based on operating conditions

Highlight assets with elevated operational risk

No changes to your control systems. No disruption to operations.

Who It's For

Operations teams responsible for critical equipment

Asset and reliability managers

Maintenance planners

Industrial and energy operators managing large fleets of assets

Benefits

Reduce unplanned downtime

Focus engineering time where it matters most

Detect abnormal behavior earlier

Improve maintenance decision confidence

Turn operational data into clear action.

See how risk prioritization can simplify daily operations.

Request a demoPowerful Features

Comprehensive tools designed to support operational decision-making

Monitoring

Monitor your systems 24/7. Track your performance with instant data flow and live charts.

Anomaly Detection

Detect problems early and intervene proactively with automated anomaly detection.

Comprehensive Reporting

Support your decision-making processes with detailed analysis reports and risk assessments.

Get in Touch

Select a topic and we'll get back to you soon.